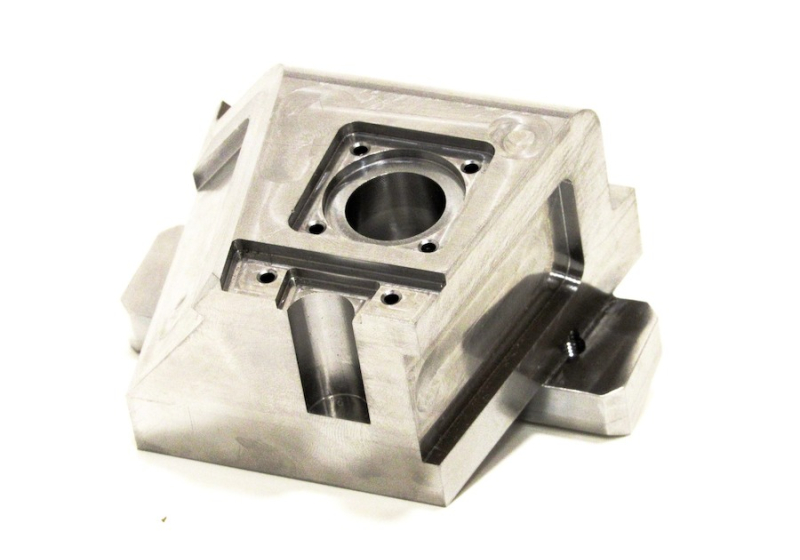

CNC machining

We perform CNC machining on a 5-axis MIKRON CNC center, type HPM 450U.

The 5-axis CNC milling center MIKRON, type HPM 450U, is a powerful five-axis device for universal production, on which we mainly carry out orders in the field of production of molds for injection molding of plastics and pressure casting of non-ferrous metals. We are also able to machine parts according to customer requirements from steel, non-ferrous metals and plastics.

Technical specifications

- Working space: Ø450 mm

- Max. table load: 200 kg

- Travel in X axis = 600, Y = 450, Z = 450 mm

- Laser measuring

- Workpiece probe

Materials

- Materials processed by 3D printing

- Ferrous and non-ferrous metals

- Plastics

Advantages of CNC machining

How it works

Block of material

The initial shape is either a block, cube or cylinder made of a material prescribed by the customer, or a shaped semi-finished product produced by 3D printing technology

CNC milling

Chip machining is based on NC code, where the source for generating the NC code in special software is a 3D CAD model supplemented by a 2D drawing with a prescription of tolerances and requirements for surface quality, heat treatment, etc.

The final part

After machining is completed, the part is removed and cleaned from the machining center and is ready for further follow-up steps such as heat treatment, polishing, etc. or directly for shipping the part to the customer